Design 4 Recycling

In the design phase it is hugely important to know the difficulties that recyclers have and how their work can be improved by better design. A good “Design-4-Recycling” will improve the recyclability of materials used.

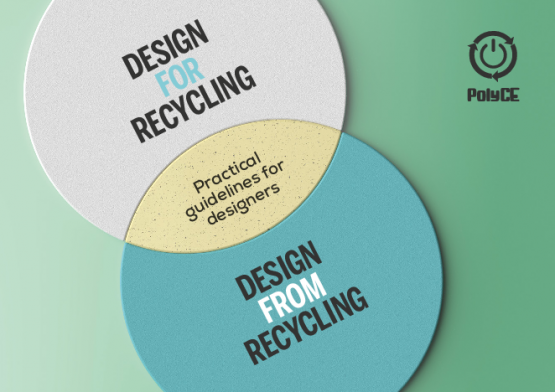

MGG Polymers is partner in the European funded research Project Poly-CE (link https://www.polyce-project.eu/ ) in which recommendations were developed for this purpose and summarised in a manual for designers.

Some of the findings are summarised as follows:

- Keep injection moulded parts reasonable in size so that they do not get lost in the recycling process.

- Make sure that the thickness of the material is > 1 mm

- Per design try to reduce the number of polymers to a minimum

- Do not use exotic polymer types, but stick to the standard polymertypes

- Use halogen free polymers

- Use thermoplastics instead of elastomers and thermosets in foams.

- Use rubber in a solid and bulky form and do not use silicon or foamed rubbers

- Avoid connecting parts permanently - mechanical fixation with moderate forces are preferred

- Choose virgin material for transparent or otherwise demanding parts.

MGG Polymers happily receives designers for an in-depth exchange of thoughts on issues like Design-4-Recycling.