Sustainability and Life Cycle Analysis

MGG Polymers is producing Post-Consumer Recycled polymers with approximately 10 % of the energy that is used to produce the same virgin polymers.

During the high-tech recycling process, MGG Polymers also uses renewable energy sources such as from the 4,140 m² Photovoltaic Energy plant on the roof of the recycling facility in Kematen an der Ybbs.

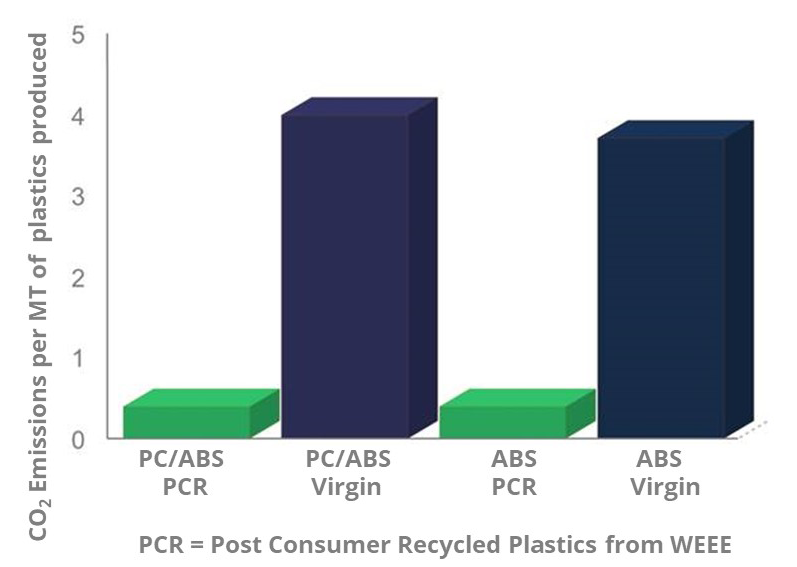

Compared to virgin plastics MGG Polymers reduces the CO2 emissions by over 4 MT per ton PCR polymers produced.

The use of PCR plastics in durable products such as electronics is by far the most environmentally friendly way in terms of energy and carbon footprint and these PCR polymers are therefore increasingly popular raw materials for the Circular Economy.

Consumers are in their thinking further ahead than what most people think. A social experiment has clearly demonstrated this (see Video PolyCE Project: A Social Experiment).

The production of virgin polymers

The original and basic raw material for polymers are produced from fossil fuels which are extracted from the earth and transported to refineries. In the refineries appropriate fractions are separated from the fossil fuels and these fractions are knitted together in large polymerization to become polymer chains.

These polymers chains are then extruded and compounded to become the virgin tech-polymers that we know as plastics. This production process is hugely energy intensive.

Raw material

- Oil is extracted

- Transported to refineries

- Non-renewable resource

- Depending on imports

Processing

- Huge refineries produce fractions

- Polymerisation plants for polymers

- Huge amount of energy needed

- Some 100 gJoule per MT

Selling

- Virgin plastics

- Produced in large quantities

- Volatile prices

- Global market

The production of PCR polymers

The MGG Polymers production method is that WEEE (E-Waste) plastics separated from the Electronic and Electric Appliances are sourced within the EU. In a first step this plastics mix is cleaned from any non-plastics materials and subsequently size reduced to a standard flake size. These flakes undergo a series of intelligent separation steps to become purified polymer flakes, which are quality controlled before being homogenized and extruded and/or compounded to become the final PCR plastic that MGG Polymers is selling.

Raw material

- WEEE (E-Waste) plastics

- Growing supply

- Produced by WEEE recyclers

- All from EU sources

Processing

- Mechanical "mining" process

- Innovative technologies

- < 10% of energy

- Save about 3-4 tons CO2/ton

Selling

- 100% PCR polymers

- Virgin-like quality

- Stable prices

- For "green" sustainable products

A detailed Life Cycle Analysis by EMPA compares not only virgin polymers compared to MGG Polymers PCR polymers, but also against the incineration of these WEEE plastics. From an environmental point of view the mechanical recycling processes of MGG Polymers is by far the preferred option of the three options compared. The full LCA document can be found HERE.