CO₂-balance as a key figure for comparability

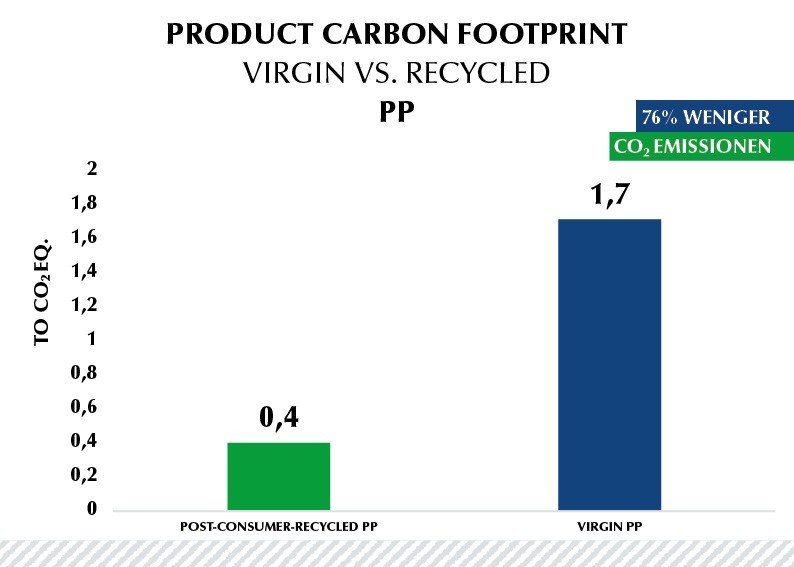

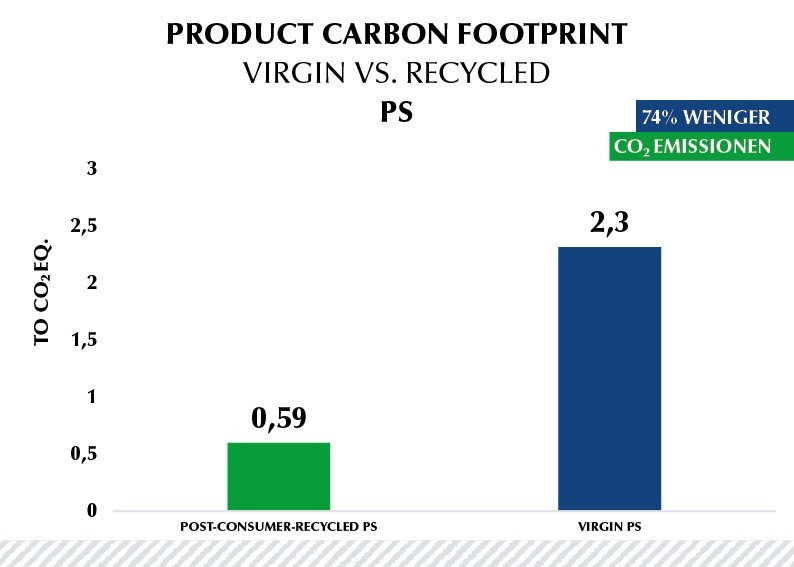

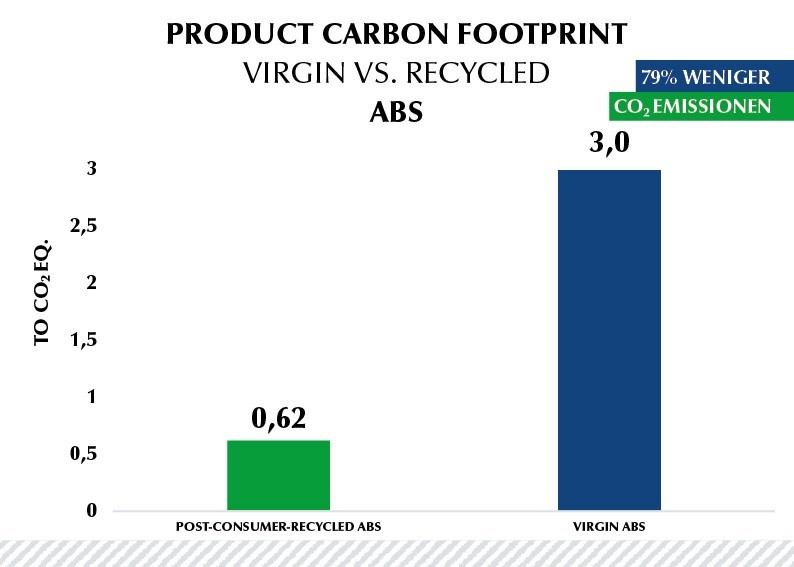

In collaboration with the independent institute Climate Partner, MGG-Polymers has calculated the CO2 footprint of the production of recycled plastic at its own plant in Kematen an der Ybbs. The result? Post-consumer recycled plastics have a significantly better CO2 footprint than virgin plastics! A fact that needs to be given more importance.

Carbon dioxide (CO2) is a so-called greenhouse gas and, as its concentration in the Earth’s atmosphere increases, it leads to global warming. CO2 is released by natural processes, but it is primarily humans who leave a significant CO2 footprint on the earth. This happens primarily through the combustion of coal, oil or natural gas – in industry or during heating. And these carbon dioxide emissions have been rising continuously worldwide since the beginning of industrialisation.

Recycling and improving the circular economy have always been firmly anchored in the DNA of the Müller-Guttenbrunn Group. Avoiding CO2 emissions and improving the carbon footprint of all of us is an important factor that gives recycling its true meaning. The plastics recycling company MGG Polymers has been working intensively on this topic for two decades. And it is no coincidence that the company motto is ‘It’s about CO2!’.

Recycled plastics save 75% of CO2 emissions.

However, the producers of high-quality PCR plastics are not primarily concerned with the climate – there is separate research for this. For Polymers, it is about the connection between what can be done within the company to contribute less additional CO2 to the earth’s atmosphere. „For 20 years, we have been in favour of giving plastics a second life and closing material cycles. Our major contribution is to try and minimise the CO2 footprint in our segment as much as possible,“ explains MGG Polymers Managing Director Günther Höggerl. „When recycling plastics from post-consumer waste, the CO2 footprint can be easily compared to the production of virgin material“, says the expert.

On average, around 75% of CO2 emissions can be saved by using recycled plastics – compared to virgin material (new plastic made from crude oil). So if you manufacture your products from recycled plastic, you in turn reduce your own CO2 footprint and that of your products.

A positive balance: CO2 footprint at our own plant.

The basis of any CO2 balancing are so-called life cycle analyses – i.e. systematic considerations of the environmental impact of products. This is a fairly complex process, but one that is now easier to carry out thanks to the use of appropriate software solutions. In order to obtain the CO2 footprint of polypropylene production, for example, data from international, harmonised databases is used. For MGG Polymers, however, it was necessary to determine the footprint of its own activities. The renowned expert Climate Partner was engaged for this purpose.

The energy and consumption data from 2023 formed the basis for the analyses now available. The calculations were programmed in such a way that they can be continuously updated with the latest data material and it can therefore be determined at any time how the carbon footprint at MGG Polymers is developing.

The CO2 footprint was calculated for the entire company, but can be shown for the individual influencing factors. „We operate our plants partly with electricity from our own generation; we only buy in “green” electricity. Heat is already partly generated using heat pumps. The vehicle fleet is constantly being converted to e-cars, and the private purchase of e-bikes by employees is subsidised by the company. We are really well positioned and optimised here“, says Günther Höggerl, analysing the current status and naming some examples of measures. „However, it has also become clear that Polymers‘ delivery and dispatch logistics still have a lot of potential for improvement. That’s why you have to start with these areas if you want to make a change.“

Lorries with bio-based diesel fuels.

This primarily refers to lorry transport in the area of delivery and distribution, which is – still – mainly diesel-powered. However, initial approaches are already being made, as there are now supplier partners who have converted their vehicle fleets to bio-based diesel fuels made from old cooking fats and oils from the catering industry. This also reduces the CO2 balance somewhat.

However, the future clearly lies in electric lorries. Shorter distances are already feasible today, but for long distances – across Europe, for example – a suitable charging infrastructure is still needed to make logistics economically viable. Unfortunately, transporting plastics by rail is not feasible or economically viable for MGG Polymers, as rail can make the most of its advantages, especially when transporting heavy goods.

Europe needs to join forces.

There have been and continue to be national endeavours to reduce CO2 emissions. However, in order to persuade industry or consumer society to commit to reducing their carbon footprint, at least Europe-wide legislation is required. Höggerl does not accept the objection that Europe alone cannot achieve anything: „Europe is an economic area with almost 500 million inhabitants. And we were the first to recognise that something had to be done!“ Of course, it goes without saying that it would be desirable to pull together globally.

What has now been agreed across Europe is the mandatory, proportionate use of recycled plastic in the production of plastic-based packaging material from 2030. Work is also currently underway on the adoption of an EU directive for the automotive industry. Here, a certain proportion of the plastics used in new vehicles will have to consist of recycled plastic.

Although the details are still being discussed, it can be assumed that the requirements will be binding from 2030 at the earliest. It will then depend on who can supply the quantity and quality of recycled plastics that will then be needed in vehicle construction. And it will be essential to determine which company can supply these PCR plastics with the lowest carbon footprint.

Complex interrelationships – a benchmark!

The impact of humans on the Earth’s ecosystem is enormous; the increase in the world’s population and the associated pressures are growing exponentially. The ecosystem is also ‘responding’ to this exponentially. Many of the sometimes complicated effects – such as the nitrogen concentration in coastal zones – are difficult to explain and are not visible. In order to describe what is currently happening on our planet, one primary parameter has been agreed upon: CO2. Extremely complex interrelationships can thus be visualised in a single detail. CO2 serves as a kind of currency – as a benchmark. And this simplifies many discussions considerably.

„You could even go so far as to say that we will trade in CO2 certificates in future“, says Günther Höggerl, looking to the future. „This would allow us to put a monetary value on our CO2 footprint. For us at MGG Polymers, that would be a great differentiator compared to other companies and an additional, attractive argument in pricing!“

A rethink in society is unavoidable.

In general, recycling is often about ‘awareness’, i.e. a clear commitment to the circular economy. „We don’t want to proselytise,“ emphasises the Polymers Managing Director, „but we want to communicate that we are committed to this topic. That’s why we have clearly positioned ourselves: ‘It’s about CO2!’. According to Höggerl, the least of the adjustments that need to be made is the technical one. Rather, plastic must be transformed from a ‘material’ into a ‘recyclable material’ in order to obtain the value it actually deserves in comparison to other materials.

This requires a rethink among the population. Nobody would carelessly throw away copper today, for example. However, 100 years of plastic development are apparently not enough to give ‘plastic’ the value it deserves. And as long as there is enough crude oil, plastics can be produced relatively easily and cheaply at any time. However, this is a very short-sighted and by no means sustainable opinion. Nevertheless, the unique selling points of plastics are obvious: they are lighter and cheaper than many other materials.

Günther Höggerl is pleased that society’s interest in recycling is steadily increasing. However, the awareness that humanity leaves an irrevocable mark with its behaviour needs to be raised even more. Consumers, the end customers, need to be made even more aware. The younger generation in particular is aware of the situation we find ourselves in. Nevertheless, responsibility cannot be left to the end customer alone; clear guidelines are needed from legislators.

A dilemma? Think ecologically and act economically.

„MGG Polymers – like other recycling companies – can only make an offer to use high-quality recycled plastics, but there is still no obligation. Legislation is needed for sustainable change,“ Höggerl reports from practical experience. This would also help those customers who would like to act sustainably, but are currently resorting to very cheap, imported virgin plastics for economic reasons. And this is exactly where MGG Polymers wants to start and establish possibilities and perspectives in order to harmonise both worlds – ecology and economy – for the producers. A task that the company in Kematen an der Ybbs is happy to take on. The biggest challenge is that MGG Polymers is, of course, also a commercial enterprise and wants and needs to be successful. Of course, it is often a balancing act, but the basic philosophy remains the same. Because: It’s about CO2!