Study confirms: the recycling of plastics is not impaired by brominated flame retardants

There was and there still is a need for discussion about brominated flame retardants in plastics. Especially for recyclers of plastics from waste electrical and electronic equipment. A very recently published new study confirms that the recycling results are not impaired by brominated flame retardants.

Sensible international regulations for the recycling of plastics are right and important. To find globally functioning concepts, plastics recycling pioneer MGG Polymers therefore repeatedly contributed its expertise at the international level. General Manager Chris Slijkhuis, as a member of the EERA Board, has held numerous discussions in recent years to achieve practicable solutions, also in the case of brominated flame retardants.

Now an exciting study has been published on this topic: the report by the leading consultancy SOFIES states that the recycling of plastics is not affected negatively by brominated flame retardants.

The initial situation

Plastics are an indispensable material with many advantages. Electronic and electrical devices would be unthinkable without plastics. However, these devices must be specially protected to avoid fires. For this purpose, brominated flame retardants (BFRs) are often used in these plastics. By using them, the relevant fire safety standards can be met to protect consumers from accidental fires. However, some BFRs are on the list of persistent organic pollutants (POPs) and are therefore considered "restricted". These restricted BFRs are sorted out in specialised recycling facilities such as MGG Polymers and sent for proper disposal, by incinerating these BFR containing plastics. This avoids any danger to the environment. However uncertainty prevails in these specialized recycling companies, as again new threshold limits for these restricted BFRs could easily become an insurmountable hurdle.

The study

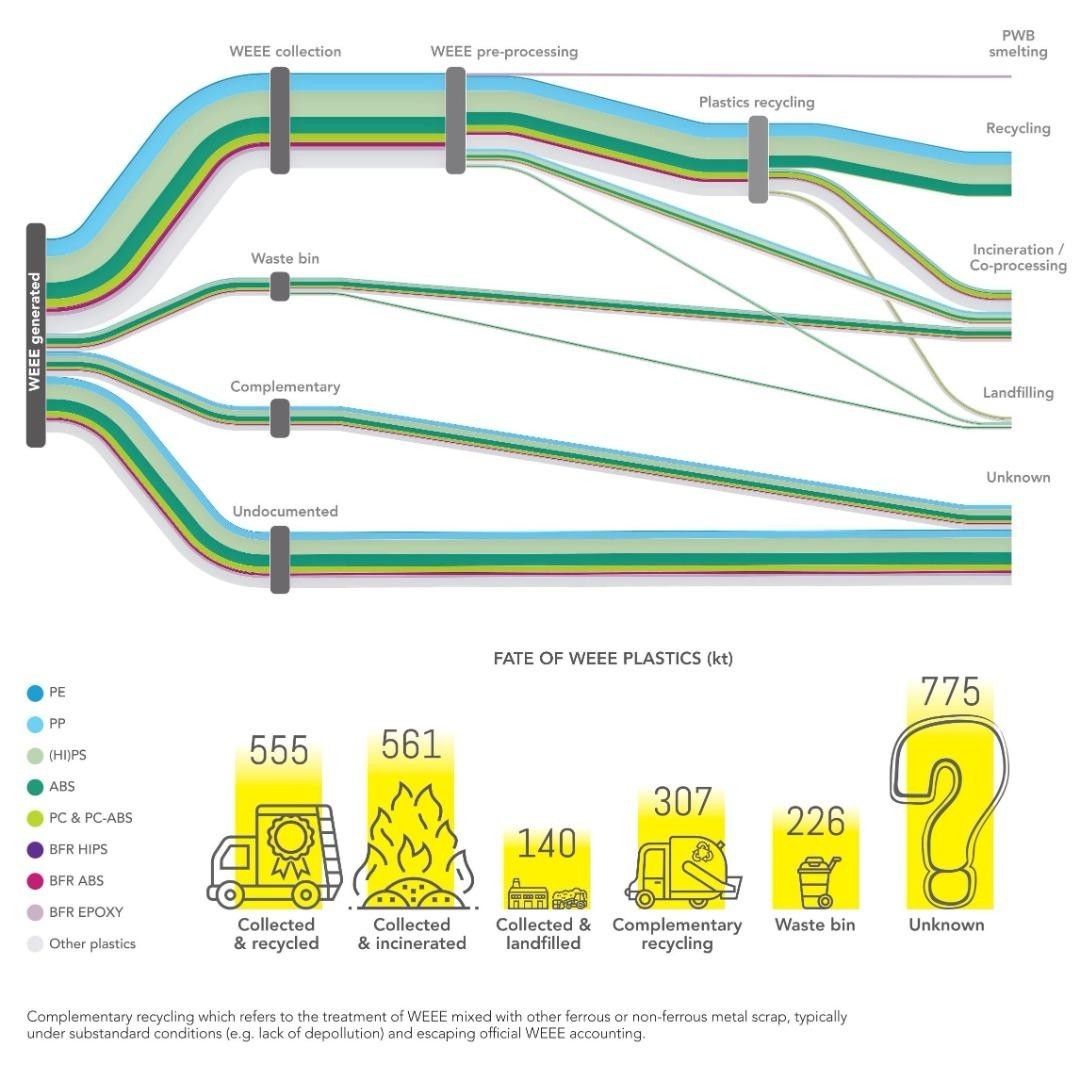

BSEF, the International Bromine Council, has recently published a comprehensive report on the flows of plastics from WEEE and their recycling in Europe. The study, prepared by leading consultancy Sofies, looks at the impact of brominated flame retardants (BFRs) on the recycling of plastics from WEEE.

The most important findings

About 2.6 million tonnes of WEEE plastics are produced in Europe every year. 9 per cent of plastics contain brominated flame retardants. One of the biggest problems: Only about half of all WEEE plastics generated in Europe are collected and subsequently recycled through official collection points. The other half simply ends up in unknown channels, such as the waste bin, and risks to be processed in low-quality recycling plants often after export.

On average, 55 per cent of plastics originating from WEEE and entering specialized recycling facilities are effectively recycled. The PCR plastics (post-consumer recycled plastics) produced in this way can then be used again to manufacture new plastic products. The study results prove one thing above all: flame retardants containing bromine do not change the recycling results compared to other flame retardants, as they are sorted out and disposed of through various processes.

EERA, the association of electronics recyclers in Europe, sees its view confirmed by the study results. So does EERA board member and MGG Polymers General Manager Chris Slijkhuis: "As recyclers of WEEE we have learned over the years how to deal with brominated flame retardants. Despite the complex mix of plastics from a wide variety of end-of-life devices, we can produce post-consumer recycled plastics that comply with REACH, RoHS and POP regulations. This is important to give consumers security of getting compliant products and at the same time to move towards a circular economy.

Danger due to the lowering of the threshold

Just like the European Association of Electronics Recyclers (EERA), Chris Slijkhuis warns against jeopardizing the progress made so far by further lowering the threshold values for restricted BFR: "The WEEE Directive requires us to screen out all brominated flame retardants - regardless of whether they are restricted flame retardants or not. In order to be able to achieve this cost-effectively, we depend on the screening of the element bromine. However, it should be remembered that we are now separating and screening more useful plastics with unrestricted brominated flame retardants."

In addition to the findings, the Sofies report also contains important recommendations for the stakeholders involved - from policymakers and equipment manufacturers to recyclers. As the European Commission is currently working on a proposal for a "Circular Electronics Initiative", the recommendations made for this initiative should definitely be taken into account.

Links:

Presentation of "E-Waste plastics recycling and its challenges...".

https://www.bsef.com/wp-content/uploads/2020/11/Presentation-Chris-Slijkhuis-EERA-at-SOFIES-Study-presentation-November-2020.pdf

and https://youtu.be/AiDLfDmGd-Q

In the press:

Euractiv: https://www.euractiv.com/section/energy-environment/news/half-of-plastics-in-electronic-waste-not-recycled-in-eu/

Euractiv: https://www.euractiv.com/section/circular-economy/interview/recycler-simpler-eu-laws-would-help-recycle-e-waste-plastics/

Who's behind the study:

BSEF, the International Bromine Council, is a Brussels-based trade association representing the international bromine industry. Founded in 1997, BSEF works to advance knowledge of the social and economic benefits of bromine, as well as its applications. www.bsef.com

SOFIES is an international consultancy company in the field of sustainability. The company was founded in 2008 with the aim of focusing on economic development and the conservation of natural resources in order to strengthen the approaches of industrial ecology and the circular economy. Sofies provides innovative solutions to improve clients' environmental, social and economic activities. Headquartered in Geneva, the Sofies Group also has offices in Zurich, Paris, London and Bangalore. https://sofiesgroup.com/en/