The cycle can be closed

MGG Polymers has been working with 19 European partners in the PolyCE project for four years. Mid-April, almost 200 participants took part in a virtual workshop - including Frans Timmermans, Commissioner for Climate Policy and Vice President of the EU Commission. A guide "Design for and Design from Recycling" was presented.

International projects always pose a special challenge. All the more so when a pandemic throws life into turmoil. However, the 20 partners in the EU project PolyCE (Post-Consumer High-tech Recycled Polymers for a Circular Economy) did not let it get them down - quite the opposite! They are pursuing the project goal of initiating a change to a circular economy for plastics with full vigor, even in these not easy times. The big goal is to use high-tech plastics already in use, such as those built into electronic products such as televisions, vacuum cleaners, IT products and other electronic products, as a source of raw materials. These tech-plastics are to be fully recycled into Post Consumer Recycled PCR plastics wherever possible.

A solvable task

Nearly 200 international participants met in mid-April for a workshop on "Circular Product Development - the Secrets of Designing for and from Recycling." How the participants would have loved to exchange ideas in person, but as is so often the case these days, it was only possible to meet virtually. The experts of the PolyCE consortium presented their experiences and findings on the holistic circular economy for high-tech plastics. The two MGG Polymers managing directors Chris Slijkhuis and Günther Höggerl also gave presentations. They focused primarily on the challenges in the individual phases of plastics recycling. They showed - as did scientists from renowned research institutions - that recycling plastics is not an easy task, but one that can certainly be solved.

Timmermans with a clear message

This clear signal to manufacturers to rely more on recycled plastics in the future was also heard by Commission Vice President Frans Timmermans, one of the architects of the European Union's Green Deal. As is well known, the EU has adopted a Europe-wide strategy to help bring ten million tons of recycled plastics back to the market in the form of new products by 2025. "For a sustainable circular economy, we need durable, reusable and repairable products. Products made from recycled materials that are in turn designed for high-quality recycling," Timmermans said.

Guide published

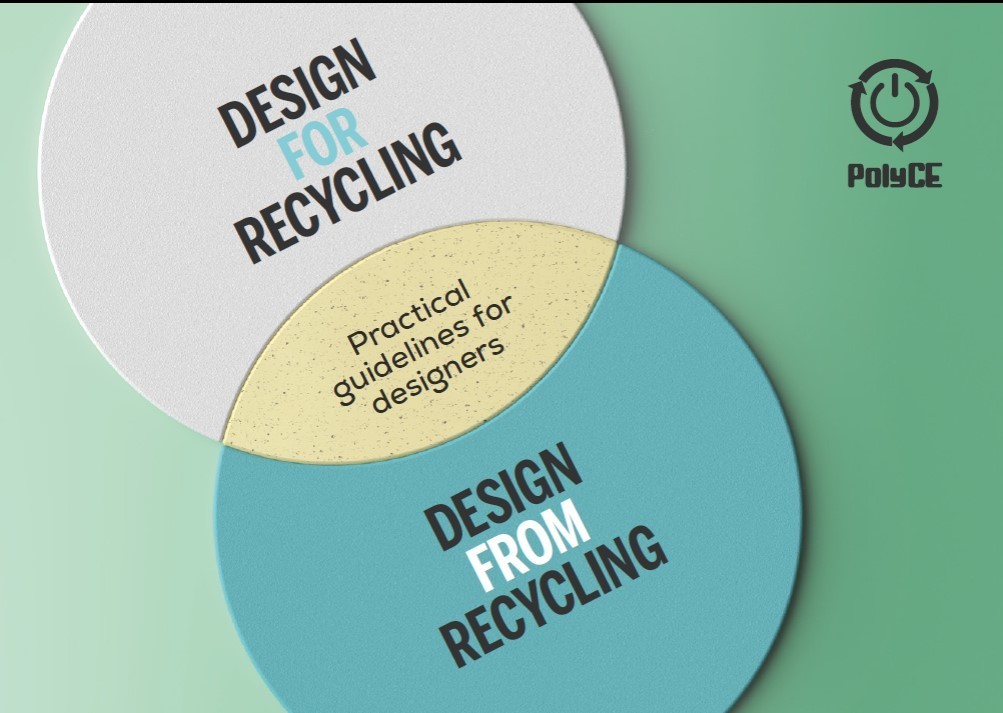

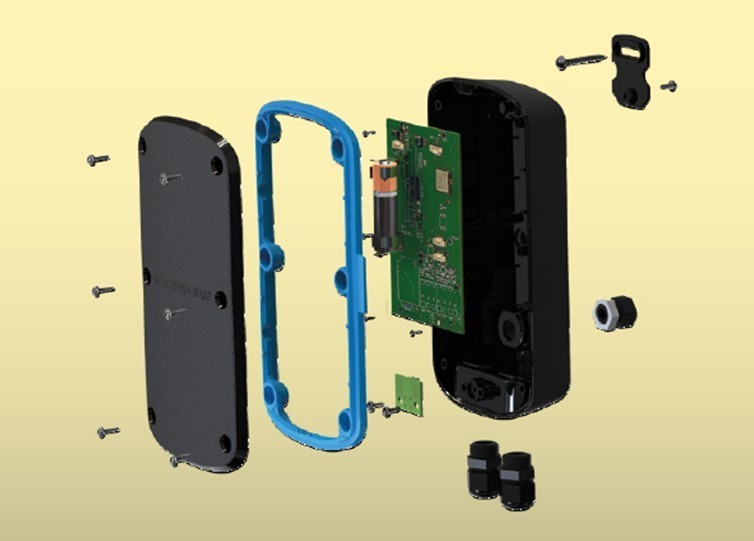

This statement could also be a shorthand for the "Design for and Design from Recycling" guide. This guide was developed as part of PolyCE and was presented at the workshop.

It contains practical advice for product designers and includes the following basic statements in abbreviated form:

1. Few common types of plastic should be used so that as much of it as possible can be recycled

2. potentially environmentally harmful product components or additives should be used as little as possible, anD if they are, then as easily removeable as possible

3. Use recycled materials

4. Material combinations/compounds should be chosen so that individual materials can be easily separated

These guidelines are considered the first coordinated guide for the electronics industry in this area. They give clear recommendations to producers, designers and other players in the value chain to be able to develop sustainable products and the guidelines contain some memorable case examples.

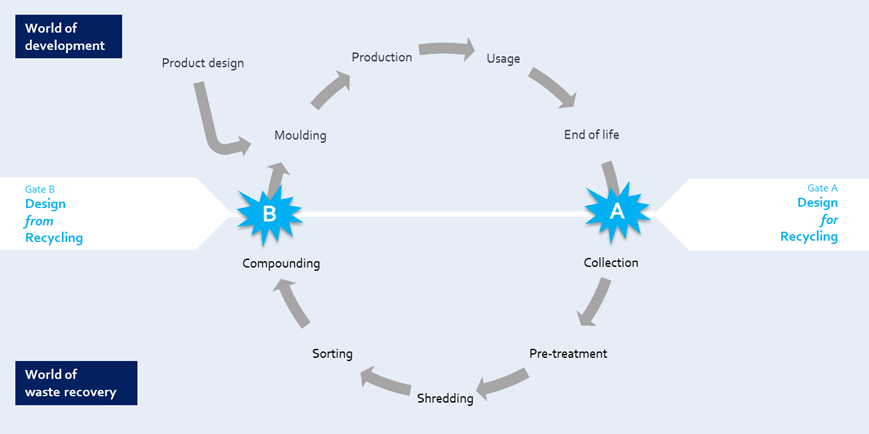

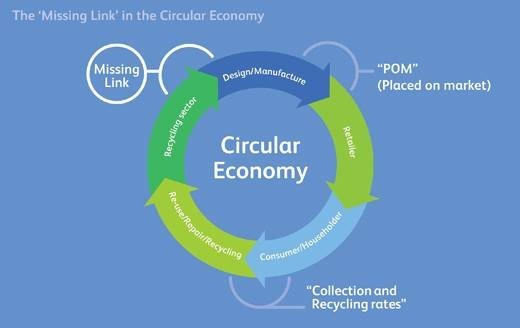

MGG Polymers Managing Director Chris Slijkhuis agrees: "I am convinced that the PolyCE project has contributed a lot to closing the 'missing link' for a circular economy. The guide that has now been published shows very clearly that if all the players in their field get involved in the coming years, it will be possible to close the loop in the use of engineering plastics."