New study sheds light on brominated flame retardants in WEEE

The Sofies study published in November 2020 already showed that the recycling of plastics is not impaired by brominated flame retardants. A NEW STUDY originally published in September 2023 by BSEF and conducted by dss+ has now shown once again that the recycling of e-waste in Europe can be made more efficient and sustainable. It provides important insights into the current state of recycling of plastics from WEEE in Europe and shows how WEEE with brominated flame retardants can be integrated into the circular economy.

Facts and figures

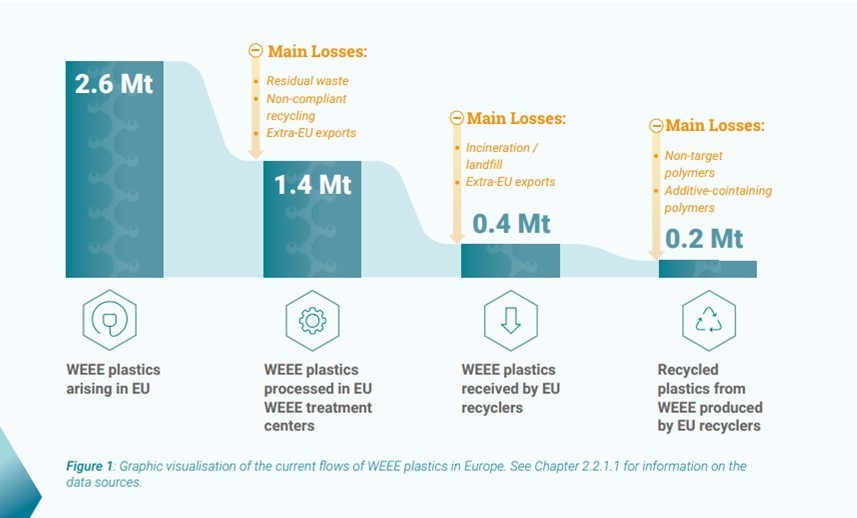

An impressive 2.6 million tonnes of e-waste are generated in Europe every year, a quarter of which consists of plastics made from various polymers including brominated or phosphorus-containing flame retardants, mineral fillers, pigments and stabilizers. A significant proportion of these plastics consist of engineering polymers, which are robust and durable, with high market value and recycling potential.

However, in 2021, only 54% (1.4 million tons) of WEEE plastics were collected through official collection points, and this means that almost 50% of these WEEE plastics often end up improperly disposed of or in undocumented processing operations, sometimes outside Europe.

The results

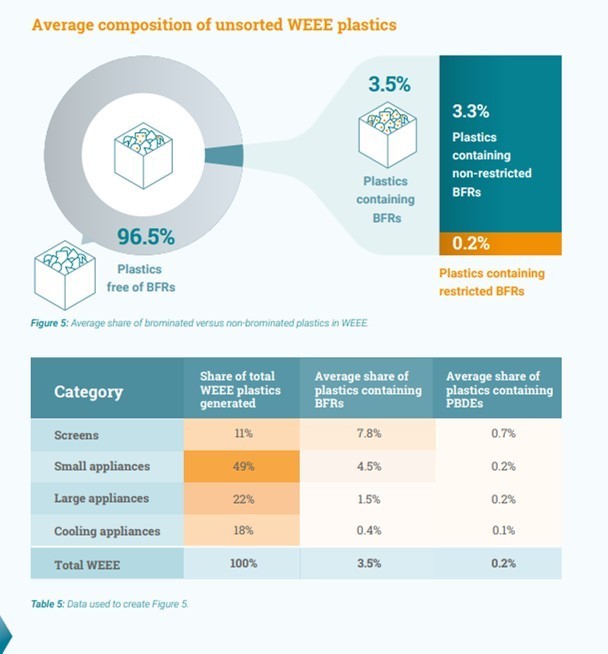

The good news: The study records a decrease in the concentrations of restricted brominated flame retardants in WEEE plastic streams. This trend is mainly due to the phasing out of some older flame retardants. For example, the share of PBDEs (polybrominated diphenyl ethers) in the total bromine content has decreased from over 20% in 2015-2016 to below 10% in 2021-2022. Nevertheless, high levels of PBDEs can still occasionally occur in WEEE streams, particularly due to older appliances manufactured before the legal restrictions came into force.

The following figures are particularly interesting:

- On average, 3.5% of WEEE plastics contain brominated flame retardants

- Only 0.2% of the 3.5%, contain restricted brominated flame retardants (PBDEs, PBBs, HBCD).

Conclusion

The main findings are: Due to historical restrictions, concentrations of restricted brominated flame retardants (BFRs) in WEEE plastic streams are decreasing. Specialized WEEE plastics recyclers can remove more than 95% of BFRs in WEEE plastics. At the same time, most WEEE plastics escape through undocumented and unregulated channels and current regulatory developments are negatively impacting the proper management of WEEE plastics.

This leads to the following recommendations for producers, recyclers and policy makers.

Recommendations for manufacturers

- Specific targets for the use of recycled materials to increase demand for WEEE plastic recyclates

- Avoid overly stringent purity requirements to encourage the use of recycled materials

- Sharing knowledge with WEEE plastic recyclers to develop recyclable and sustainable products.

- Examine how the design and use of recycled materials can influence recycling processes (e.g. reducing the use of certain additives, etc.)

Recommendations for recyclers

- Develop innovative sorting and recycling processes to recover a wider range of plastics

- Establish long-term partnerships with manufacturers to make product design recycling-friendly and select materials that are easily recyclable (see also NEWS article "Design for/from Recycling")

Recommendations for policy makers

- Incentives to increase the collection of WEEE

- Regular data collection and analysis to develop data-driven guidelines and the harmonization of thresholds in the POPs Regulation.

- Creation of regulatory structures to facilitate the smooth flow of WEEE plastics to the certified recycling networks

About BSEF:

BSEF – the International Bromine Council, is the global representative body for bromine producers and producers of bromine technologies. Originally founded in 1997, BSEF works to foster knowledge of the societal benefits of bromine and its applications.

About dss+:

dss⁺ is an international Consulting company specializing in safety and operations management with the goal of saving lives and creating a sustainable future. dss⁺ helps companies build organizational and people skills, control risks, optimize operations, achieve sustainability goals and operate responsibly overall.

LINKS:

Video presentation study:

https://www.youtube.com/watch?v=xVqE4l-L0Gk

ABBREVIATIONS:

BFR Brominated flame retardants

PBDEs Polybrominated diphenyl ethers

POP Persistent organic pollutants

Copyright images:

© 2023 DSS Sustainable Solutions Switzerland SA. All rights reserved.